La tomografia Computerizzata Fan Beam si basa su detettore di raggi X ad 1-dimensione ed una sorgente di raggi X, che creano sezioni (cross-sectio) a 2-dimensioni dell'oggetto in esame.

La tomografia Computerizzta Cone Beam è invece basato su un detettore di raggi X 2-dimensioni ed una sorgente di raggi X, che crea proiezioni di immagini 2-d che saranno poi utilizzate per ricotruire le immagini in cross section.

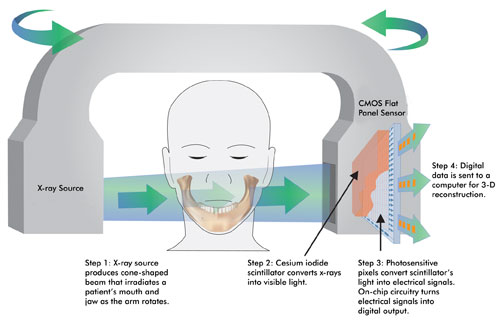

La sorgente di raggi X emette un raggio di forma conico (cone shaped) che investe l'oggetto da esaminare e poi si dirige su un detettore. Il detettore è composto da:

– uno scintillatore: un materiale (es. lo ioduro di cesio) capace di generare luce una volta investito dalle radiazioni ionizzanti.

– un transduttore: la luce generata dallo scintillatore arriva ud un transduttore, che converte il segnale ottico (fotoni) in segnale elettrico (elettroni). Il trasduttore è un semiconduttore, generalmente silicio e suoi composti, utilizzato con diverse tecnologie (CCD, CMOS, Silicio Amorfo) che registra le informazioni e le converte in segnale prima elettrico e poi digitale, che verrà utilizzato per ricotruire l'immagine. E' la stessa cosa che accade in una fotocamera.

Quindi l'informazione che viaggia con i raggi X viene prima convertita in fotoni da uno scintillatore e poi in elettrone da un semiconduttore. Poi l'elettrone viene convertito in segnale digitale che permetterà di ricostruire l'immagine con l'ausilio di un algoritmo.

CMOS technology for digital dental imaging

John Gilmore, Jennifer Weldon and Maridel Lares, Hamamatsu Corp.

The dental industry is continually changing, with more and more dentists adopting the latest digital x-ray technology into their practices. The driving advantages of digital x-ray systems versus film-based systems include the following: increased work flow, high-quality x-ray images for improved diagnosis and reduced radiation exposure for patients. Digital systems are based primarily on two sensor technologies: CMOS (complementary metal oxide semiconductor) and CCD (charge-coupled device). This article focuses on the key features and benefits of CMOS technology used in the dental field.

Digital x-ray systems are used for three imaging modalities for dental diagnosis: intraoral, panoramic and cone beam computed tomography (CBCT). Intraoral systems, used for taking horizontal and vertical bitewings, provide dentists with detailed images for enhanced diagnosis. Panoramic systems, which scan a patient’s entire mouth, often use time delay integration (TDI) technology. CBCT equipment takes slices of images, which are then reconstructed to form a three-dimensional image of a patient’s entire jaw and mouth. These imaging systems use scintillators, which convert x-rays into visible light, and solid-state sensors, such as a CMOS device, which detect the scintillator’s emission.

A CMOS device converts light into a digital signal using photosensitive pixels and on-chip circuitry. CMOS technology has a limited photosensitive area and higher noise compared with a CCD, but the noise level has been improving. CMOS has several useful characteristics: It requires low power to operate, has high-speed readout, is capable of on-chip integration of electronic circuitry and produces digital signals without external converters.

Cone beam computed tomography

CBCT, also known as cone beam volumetric tomography (CBVT) or cone beam volumetric imaging (CBVI), generates 3-D images of the teeth and head using x-rays and computer software. It was introduced in Europe and Asia in the late 1990s, followed by its introduction in North America in 2001.

“The adoption is huge,” said Dr. Dale A. Miles, a diplomate of the American Board of Oral and Maxillofacial Radiology. Miles, who also analyzes cone beam computed tomography data from dentists across the nation, said, “The early adopters [were] the orthodontists and oral and maxillofacial surgeons. But periodontists and endodontists are jumping right in there big time, especially because of the smaller field-of-view machines that have come out.”

Dental specialists and surgeons use the data from CBCT for placement of dental implants, third-molar (wisdom teeth) extractions, TMJ (temporomandibular joint) evaluations, orthodontic treatment planning, surgical planning and others.1 Each type of dentist requires a different CBCT field of view.

According to Miles, periodontists need a small field of view (6 x 6 or 8 x 8 cm) for implant placement. Endodontists need the same field of view for implant surgery on failed endo teeth and a smaller one (4 x 4 cm) for root canal therapy. For surgeons, an 8 x 8-cm field of view is sufficient for extractions, but a larger one is needed for trauma cases and orthognathic surgery. Orthodontists require the largest field of view to measure angles and lengths of anatomical landmarks for treatment planning.

To generate 3-D images, a CBCT machine captures x-ray images of a patient’s head, which computer software then reconstructs into a 3-D image within a few minutes. In a CBCT machine, an x-ray source and a sensor are placed 180° apart on a rotating arm, and the patient is placed in the middle (Figure 1). CBCT uses a cone-shaped x-ray beam to acquire a volume of data at each frame, generating a complete 3-D image (Figure 2) in one rotation or less. It requires a much lower dose of radiation than medical computed tomography (CT), a benefit to patients.

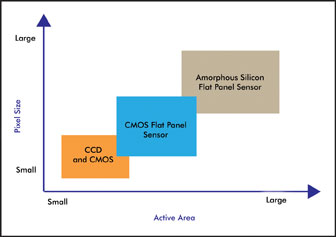

The sensors used in CBCT machines are amorphous silicon (α-Si) flat panels, CMOS flat panels or image intensifiers coupled to a CCD. CMOS flat panel sensors have advantages and disadvantages compared with α-Si flat panels. One advantage is smaller pixel size, resulting in higher resolution (Figure 3). Also, unlike α-Si flat panels, CMOS flat panels do not suffer from image lag, a residual charge left behind in the sensor that degrades overall image quality. It is especially troublesome in CT applications because there is no time to correct for it by reading the same exposure repeatedly until all the signal is read out and summed and the pixels completely reset.

A disadvantage of CMOS flat panel sensors is the size of the active detection area. It is difficult to produce a single CMOS chip in a large size, unlike α-Si flat panels. A common technique to overcome this issue is tiling multiple CMOS chips to form a larger mosaic.

Amorphous silicon and CMOS flat panels are used in many of the CBCT machines available today. These machines differ in field-of-view sizes, scanning time, patient position (standing, seated or supine), software and other parameters. They cost approximately $100,000 to $250,000, so many purchases typically are made by multidentist clinics or imaging centers. However, dentists who don’t own a machine can still benefit from CBCT images.

“Even if the dentist doesn’t buy a machine, [he or she] can access the data from it,” Miles said. “That’s a big plus for dentists. They don’t need to commit to a large capital outlay. They can get the volume information in terms of the DICOM [Digital Imaging and Communications in Medicine] data set, and put it in software to get out better data for their implant, or for their orthodontic procedure or for a third-molar extraction.”

Panoramic imaging

Besides CBCT, panoramic imaging also uses CMOS technology. Dentists use the panoramic mode to image the entire set of teeth and parts of the jaw in a single view for placement of dental implants and assessment of TMJ disorders, sinus infections and other problems. As with a CBCT machine, a panoramic machine has an x-ray source and a sensor placed 180° apart on a rotating arm. The arm rotates around a patient’s head and scans the entire jaw, generating an x-ray image. Within a minute, the entire process is complete, without causing any discomfort.

Solid-state sensors used in digital panoramic machines are generally a CCD image sensor or a CMOS flat panel sensor. A common CCD readout technique for panoramic imaging is TDI. In this mode, the rotation of the x-ray source is synchronized with the readout of the CCD, enabling continuous imaging and accumulation of signal.

A CMOS flat panel sensor can be used for panoramic imaging by reading out only a narrow strip of its active area. This sensor has both advantages and disadvantages compared with a TDI-CCD. The main advantage is ease of use for the system designer. The output of CMOS devices is already digital, so external signal processing and digitization are unnecessary. The main disadvantage of a CMOS flat panel sensor is higher readout noise than a TDI-CCD and higher signal accumulation in the digital domain, adding to the total noise.

CMOS technology is versatile and meets the needs of the dental industry for simple and complex imaging modes.

References

1. D.A. Miles (2009). The agony and ecstasy of buying cone beam technology, Part 1: The ecstasy. Journal of Implant & Advanced Clinical Dentistry, Vol. 1, No. 1, pp. 19-31.

2. D.A. Miles and R.A. Danforth (2007). A Clinician’s Guide to Understanding Cone Beam Volumetric Imaging (CBVI). Pennwell Press.